Features

Operating Benefits 7” color touchscreen with user-friendly interface and clear prompts PLC with job storage, batch counters, packaging statistics, and login-in levels Built in self-help diagnostics for troubleshooting Compact design takes up minimal footprint in the packaging area Standard operating height of 34.5” (4 height settings – 30.5”, 32.5”, 34.5”, 36.5” ) Set-Up Benefits Utilizes Rollbag pre-opened bags-on-a-roll for quick bag size changes and easy set-up Use with poly tubing (optional), for lower material costs and ability to set bag length on the fly Interface ports to integrate counters, scales, and robotics Adjustable height load shelf to support the bag (up to 18” length) during packaging Ceramic heating element for fast start-up Maintenance Benefits Off the shelf modular components for easy replacement Remote networking capability for improved troubleshooting Self-diagnostics ensure quick problem solving Quick service access to all pneumatic and electrical components Comprehensive 5 year warranty (optional) which includes consumable parts & labor Safety Benefits Low pressure seal bar closing with obstruction detection Low power consumption design (1100 Watts) Safety cover protects access to the seal bar (when using a funnel) CE compliant design for improved safety and troubleshooting

Options

Operating Options

- Footswitch

Instead of using the start button, the cycle is activated via a foot switch. With this option, the operator can have both hands free during filling of the bag

- Hand Activation Sensor

This sensor detects the presence of the operator’s hand above the loading area. Once the operator drops in the product and removes their hand from the loading area then the machine automatically cycles. This sensor eliminates a step in the packaging process, as the operator does not need to press a button or activate a foot switch to cycle the bagger.

- Product Detection Sensor

When the product detection sensor detects the product in the bag, the seal bar closes and seals the bag. The sensor is mounted underneath the seal bar and can be moved along the load shelf.

- Adjustable Seal Bar Opening

This option reduces the stroke of the seal bar to be slightly greater than the bag opening which increases the packaging speed. Ideal when using small bags.

- Articulating Bag Support

This option supports the bag during the sealing process. At the end of the cycle the load shelf tilts down at an angle, dispensing the bag to the next step of the packaging operation. The maximum bag length with the standard articulating bag support is 18”.

- End of Roll Sensor

This sensor detects when the roll of bags is nearly empty and stops the bagger in order to allow changeover to a new roll of film

- Elevated Machine Frame

The elevated machine frame is designed for those that have bags longer than 24” and want to put a conveyor underneath it. This option is also used for tall operators that want to pack products while standing, as the loading height would be great than 36”.

- Bag Open Sensor

The Bag Open Sensor assures that when a bag is in the load position it is open and ready to accept product

- 220V Operation

With this option, the bagger will work with 220V single-phase electricity. This option is designed for packaging locations that do not have 120V available, or those that want to use a lower amperage circuit in conjunction with 220V.

Material Options

- Seal Flattener Fingers

Seal Flatteners work to hold bag taut during sealing to minimize wrinkles. Bag in open position before bag is stretched for sealing.

- Air Expeller

The air expeller is a plate with a foam pad. This device presses against the bag prior to sealing, removing excess air.

- Static Eliminator

This option removes static electricity that could be in the bags, The eliminator neutralizes the static charge and is especially beneficial with thin bags.

- Adjustable Hole Punch

Pneumatic punch that puts a small perforated hole (flutter vent) in the bag, allowing for excess air to escape.

- Film Perforator

The film perforator has an upper and lower assembly which creates a vertical perforation along the complete length of the bag. This perforation allows air to vent out of the bag after it has been sealed.

- Film Guides

The film guides assure that the packaging material goes straight into the bagger by keeping the film in a fixed position. This option is ideal for narrow bags and poly tubing.

Poly Tubing Options

- Bag Maker Assembly

The bag maker assembly allows the R3200 bagger to use poly tubing, in addition to pre-opened bags on a roll. With poly tubing, the user can change the desired bag length at the push of a button since the bag is made-on-demand. The assembly applies a bottom seal to the tubing, as well as perforates and opens the material, prior to loading. When using poly tubing the R3200 will run up to 40 bags/min (dependent on bag size, gauge, and product).

- Print Registration Sensor for use with preprinted film to center graphics on the finished package.

- A Horizontal Perforation option is used to create a perforation on the bag.

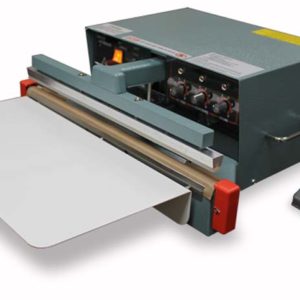

- Seal Bar with Hang Hole

A seal bar that also creates a hang hole near the top of the bag to allow a package to be placed on a retail display hook.

- Chain Bags

More than one bag or compartment can be made out of the Poly Tubing before being separated.

A strip of bags can be made.

- Tear Notch

This option creates a tear notch which allows a bag to be easily opened by the customer.

Printing Options

- Thermal Transfer Printer

If you need to print large text, images, or barcodes on your bag, then a thermal transfer printer is the right solution. Our Videojet thermal transfer printers are available in various widths, to accommodate different printing requirements. Additionally, printing software is available in order to make print set-up a breeze.

- Inkjet Printer

If you need to print small text, date, time, or logos on your bag then an inkjet printer is the way to go. This compact inkjet printer allows you to print information that is up to 1/2″ high by up to 36″ in length

- Label Printer Applicator

Integrated label printer applicator ties into warehouse management system to print and apply a label directly on the outside of the bag.

Product Loading Options

- Fixed Funnel

The funnel guides the product into the bag. The funnel is mounted above the seal bars and can be used for manual or automatic filling. It is made of stainless steel and comes in a range of sizes.

- Accumulating Funnel

The stainless steel accumulating funnel is designed to accumulate parts prior to being dropped into the bag. This type of funnel is optimal when a feeder is used. The accumulating funnel allows the feeder to keep feeding parts while the bagger cycles. It also ensures that multiple parts get dropped into the bag at one time, as the funnel only opens when the bag is in position

- Easy Load Bag Opener

Several features in one! First, this system creates a square or rectangular opening for ease of loading product into the bag. Second, the system physically grips the bag to support heavier products in the bag. Last, the easy load bag opener includes seal flattener fingers, which stretch the bag tight prior to sealing, minimizing wrinkles in the seal area.

- Bag Holder

The bag holder is useful for getting a straight seal when packing free-flowing bulk products. It can also be used as an anti-stick device to prevent light bags from sticking to the sealing bar.

- Sorting Table

A prep area placed on top of the machine, allowing the operator to prepare the products that will be packaged.

- Sorting Table with Frame

A prep area that is placed over the top of the machine. This provides a space for the operator to prepare the products that will be packaged.

Feeding Options

Outfeed Options

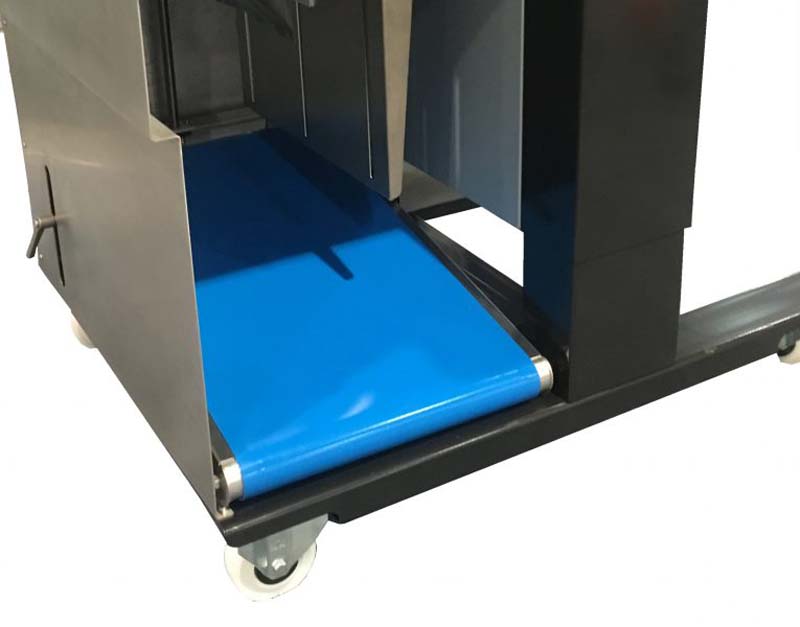

- Bag Support Outfeed Conveyor

Instead of a load shelf to support the bag, it is possible to use a bag support outfeed conveyor. This conveyor supports and lifts the bags during sealing, then the sealed bags are transported to the left or right side of the bagger. This conveyor allows the operator to comfortably stand or sit in front of the bagger during packaging.

- Outfeed Conveyor

The outfeed conveyor transports bags from the bagger up to table height. With every cycle of the bagger, the conveyor indexes one step. It consists of a horizontal section where the bag is dropped and an inclined section which has a height of approximately 35”. The height and angle of the inclined section are adjustable. The conveyor is made of stainless and equipped with casters. The outfeed conveyor is available in 10″ and 16″ widths. The conveyor can be put in front of the bagger, like in the picture, or to the side of the machine.

Maintenance Options

- Comprehensive Warranty

- Light Warning Tower

- Wifi Interface

- Spare Parts Kit

This kit includes basic consumable and replacement parts for the machine. These parts include PTFE seal bar cover, pressure rubber, and perforation knife

Safety Options

- Dual Touch Start Switch

Two switches that must be touched simultaneously in order for the machine to cycle. This ensures hands and fingers are not in the seal area while the machine is cycling.

- Safety Circuit

- Light Curtain

Prevents the operation of the bagger when the optical detection field is obstructed. Can also be used to trigger the start of the cycle, once the obstruction is no longer detected.

More Options

- Touchscreen Cover

A clear plastic cover that protects the touchscreen from dirt, dust, and damage.

Div Table styles are a great way to layout website sections on the page! Make sure you bookmark this useful free online HTML tool!