Features

BENEFITS

- Cobalt Dichloride Free Humidity Indicator Cards are free of Cobalt-Dichloride (CoCl2), a chemical which has classification and labeling requirements under the European Chemical Agency (ECHA) REACH directives

- Fully compliant with JEDEC standard J-STD-033 for color-change accuracy

- Meets all relevant ECB/REACH labeling requirements

- Typical applications include the dry packaging of semiconductor and electronic devices

COMPATIBILITY

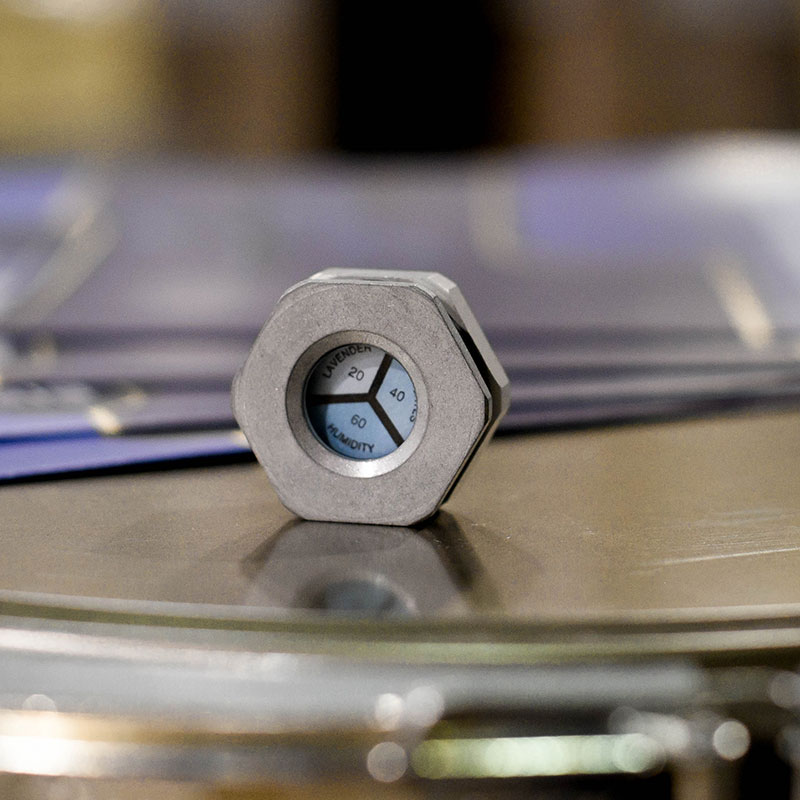

Plugs are compatible with rigid-wall equipment and electrical housings, as well as most flexible barriers. Desiccator plugs are primarily designed for small containers, mechanical boxes or sealed instruments where space is limited.

Plugs are adaptable to virtually all applications for Method II packaging of Mil-Std-2073-1D Method 50 and AS26860 aerospace specifications. Compact plugs are designed to be leak-resistant and temperature-proof, and to withstand

shock and vibration.