High Speed and Low Cost of Ownership

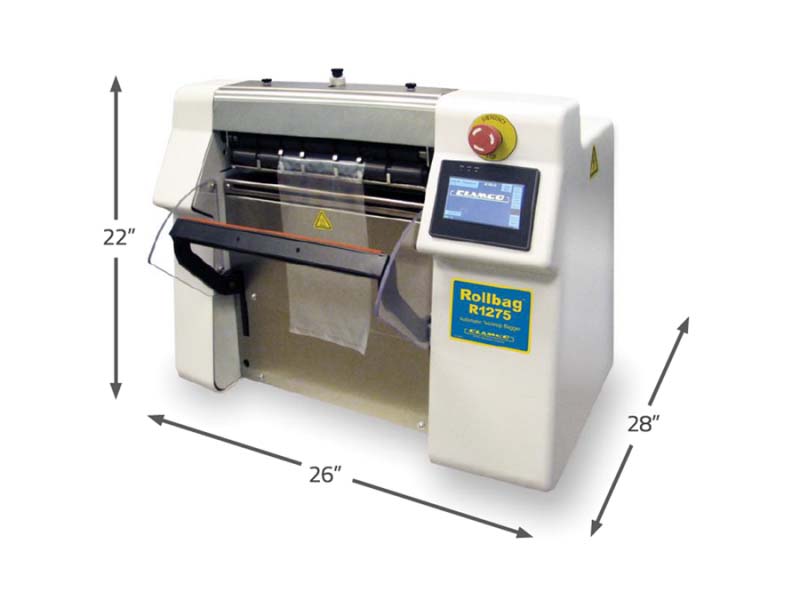

Operating at speeds up to 60 bags per minute, the Rollbag R1275 Automatic Bagger is the fastest automatic bagger in its class. This exceptionally rugged and versatile automatic bagger is designed for multi-shift production, matching the performance of automatic baggers costing thousands more. The high performance of this automatic bagger is accomplished through continuous development of a time tested platform, a powerful PLC, and a unique stepper motor drive.

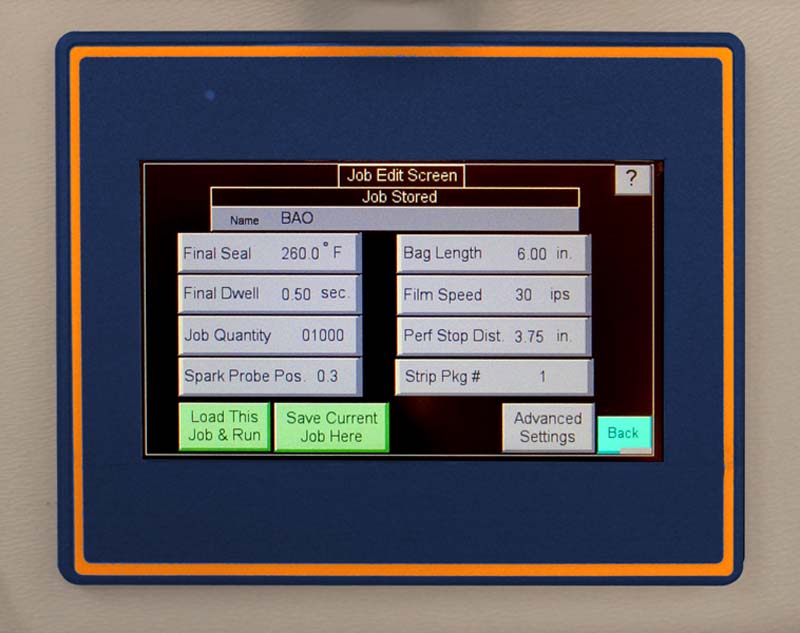

Easy Touchscreen Programming

An Easy touchscreen programming provides a flexible solution to fast-changing production requirements. With the ability to store up to 20 job profiles, the Rollbag R1275 Automatic Bagger empowers front-line operators with the ability to make intuitive job changeovers without reprogramming, thus minimizing the requirement for costly managerial involvement. Easy to learn and easy to use, help screens and built-in diagnostics ensure optimum performance and productivity. Perfect for cramped work areas, the Rollbag R1275 is compact and has a small footprint.

Use with a Variety of Bags, Printing Options, and Feeding Devices

Like the Rollbag 1075, the Rollbag R1275 uses Rollbag brand pre-opened bags on a roll for fast polybag packaging. This automatic bagger can be used with counters, scales, and other feeding devices. The Rollbag R1275 also has the ability to connect with robotics and other external devices easily. An optional thermal printer enables the printing of graphics, bar codes, date codes, and text. The Rollbag R1275 Automatic Bagger delivers exceptional value, speed, and flexibility for poly bagging operations.

Safety

Safety features on this automatic bagger include low-pressure jaw closure, jaw obstruction detection, unobtrusive guards, and a prominent emergency stop button. The 220V version of the Rollbag R1275 Automatic Bagger is designed to meet CE requirements.

Extendable Warranty

The Rollbag R1275 Automatic Bagger is made in the USA and includes a 1-year limited warranty, extendable up to 5 years when exclusively using Rollbag brand pre-opened bags on a roll or poly tubing!

Leasing Options from $200/month