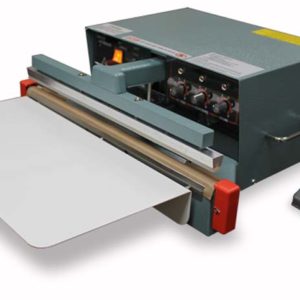

Easy to Use, Compact Automatic Bagger

The Rollbag R1075 Automatic Bagger is the most cost-effective, automatic tabletop bagging system available till date. This automatic bagger is compact, lightweight, fast, and easy to use. The Rollbag R1075 Automatic Bagger combines a powerful electric drive motor with pneumatic force to present and open bags for filling, then seal and separate the filled bag.

Utilize a Wide Variety of Bags

Rollbag brand pre-opened bags on a roll, ranging in size from 2″ x 3″ to 10″ x 20″, make this automatic bagger highly flexible. Poly bags can be presented one at a time or in attached sets of strip packages for kit packaging.

User-Friendly Controls

A simple, sequential interface enables quick programming. The storage of 10 job profiles enables fast and easy changeover for bagging different products. This automatic bagger can be triggered via a foot pedal, the control panel, or other optional devices (e.g. photo-eye, palm button, automatic signal). Simple maintenance combined with quality parts and technical support to maximize dependable production time when using the Rollbag R1075 Automatic Bagger.

Compatibility

The Rollbag R1075 Automatic Bagger can be used in semi-automatic or fully automatic polybag packaging. This automatic bagger can be hand loaded, or it can be interfaced with automatic counters, scales, and other feeding devices. The addition of a hot stamp printer enables the user to apply date and lot codes to their packaged products.

Safety

Safety features on this automatic bagger include low pressure jaw closure, jaw obstruction detection, unobtrusive guards, and a prominent emergency stop button. The 220V version of the Rollbag R1075 Automatic Bagger is designed to meet CE requirements.

Extendable Warranty

Simple maintenance combined with quality parts and the technical support maximize dependable production time when using the Rollbag R1075 Automatic Bagger.

The Rollbag R1075 Automatic Bagger is made in the USA and includes a 1-year limited warranty, extendable up to 5-years when exclusively using Rollbag brand pre-opened bags on a roll or poly tubing!

Leasing Options from $170/month