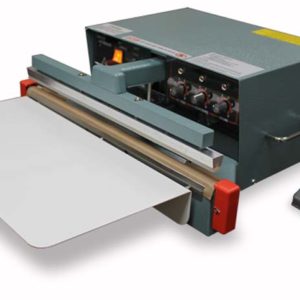

Automatic Pouching System

The Rollbag Magnum HS Med Automatic Bagger is a medical pouch sealing system for automatic packaging. This medical pouch sealer is capable of being independently validated, and it is designed for clean room use and can package products at speeds of up to 40 bags per minute using Tyvek® Poly or medical-grade paper rollstock (subject to material spec and bag size). Products packaged on the Rollbag Magnum HS Med Automatic Bagger are suitable for use with an autoclave or sterilizer.

The Magnum HS Med validatable medical pouch sealer bagger features a control system that monitors all seal parameters and switches into alarm mode if any parameter goes out of range. External ports on this medical pouch sealer bagger enable the user to reliably conduct the sealing parameter validation process. The Magnum HS Med can also communicate with a remote device for central monitoring.

A step up from conventional medical pouch sealers, the versatile Magnum HS Med features an easy-to-operate, automatic pouch making system using tubing. This bagging solution provides the benefits of faster fill speeds (up to 70 bags per minute using polyethylene tubing) as well as the ability to change bag dimensions quickly and easily. The Magnum HS Med automatic pouching system creates a chevron seal for peelable pouches, and may be configured to create a straight seal on poly tubing and a variety of other materials.

The Magnum HS Med medical pouch sealer, automatic bagger delivers the latest technology in a high-speed automatic pouch sealing system. Bag length changes are accomplished quickly using built-in job storage feature and the large, easy to use, touchscreen display. Help and diagnostic screens are built into the operating system to ensure optimal performance and maximum uptime. The controller interface simplifies integration of counters, scales, robotics and other feeding devices for improved automation and faster filling. By adding a thermal transfer printer, the operator can print graphics, bar codes and text right on the bag.

The Rollbag Magnum HS Med automatic medical pouch sealer delivers a number of key benefits to the customers and is a perfect fit for a dynamic, fast-moving production environment. The validatable pouch sealer bagger is easy to use, accommodates a variety of packaging materials and sizes, adapts quickly to changing production demands, and requires very little maintenance. When all the benefits are combined, the result will lead to a significantly lowered total cost of ownership.

The Rollbag Magnum HS Med automatic medical pouch sealer bagger is made in the USA and includes a 1 year limited warranty.

Leasing Options from $690/month

Tyvek® is a registered trademark of E. I. du Pont de Nemours

It seems to be impossible, but it’s actually easy to

solve a Rubik’s Cube using algorithms.