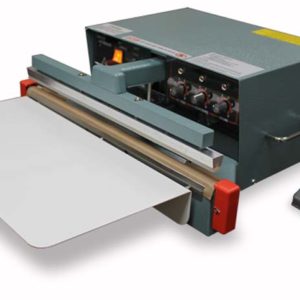

Semi-automatic sleeve wrapper

The Clamco 7130MSW is a semi-automatic sleeve wrapper for shrink bundling applications. The intermittent motion inline 7130MSW produces packages with open ends, commonly referred to as a “bull’s-eye”. This bundler can be used for wrapping a wide range of products, including trays, cartons, and bottles. The 7130MSW can deliver an output of up to 600 packages per hour. This sleeve wrapper is designed for use with 1.2–4 mil polyethylene film and is well suited for bundling applications in the food, beverage, and contract packaging industries.

Enhanced microprocessor technology

The Clamco 7130MSW Semi-Automatic In-Line Shrink Wrap Bundler utilizes an enhanced microprocessor for easy set-up and monitoring. The modern, easy-to-use display indicates all key packing statistics, including production rates and efficiencies. With a 20-program memory and fast set-up, commonly packaged products are just a click away.

Boost productivity

The Clamco 7130MSW wraps up to 10 packages per minute to enhance productivity and shorten packaging run cycles. The 7130MSW has a pneumatically operated 30-inch wide seal bar that ensures exceptional seal integrity. The 7130MSW seal bar is constantly heated with a cold knife for faster sealing and minimal downtime. A product hold down prevents package tipping and reduces film tension during the sealing process. Adjustable speed transition conveyor between the wrapper and the tunnel provides a smooth product transition, and a patented, heat-resistant fiberglass tunnel belt enhances film shrinkage and provides excellent package stability. The integrated heat tunnel features independent air flow controls for optimized shrinking. Plus, the Clamco 7130MSW has automatic product length detection for standard packages and pre-programmed length for irregularly shaped products. Film roll replacement is made easier via rollers on the film unwinders.

The 7130MSW Sleeve Wrapper semi-automatic in-line Shrink Wrap Bundler with Unitized Tunnel includes a 2-year limited warranty.

Leasing Options from $590/month

The solutin of the Rubik’s Cube is not easy but it can be caclucated with an online program. Launch the cube solver program in your web browser to give it a try.