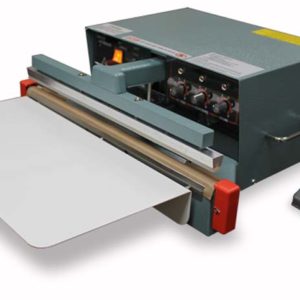

Features

Performance Features

- Adjustable height sealing jaws (up to 7.5″ high) accommodate a wide range of product heights

- Alignment guides make product placement easier

- Power film unwind with variable speed, adds smooth

film and product timing - Heavy duty, mushroom style hot knife sealing system for an 18″ x 23″ seal area

- Horizontal and vertical product sensors improve usability

- Standard FDA infeed belt provides food application versatility

Interface Features

- Product memory for up to 20 package configurations make changeover fast and easy

- Touchscreen interface with diagnostics for precise user control

- Multiple user levels: operator, supervisor, and technician to ensure programming is consistent through multiple shifts

- Machine can be combined with our 4T or 4T Double Tunnel for optimum shrink packaging

Operating Features

- Front loading film cradle with film separator and static eliminator for convenient, smooth operation

- Fast package size changeover

- Self-adjusting trim take-up reel neatly winds trim

- Micro perforators deliver uniform air evacuation

- Casters and levelers for improved mobility

- 23″ maximum film width—perfect for medium-size packages

Safety Features

- Adjustable foot pads to ensure operator safety and machine stability

- Interlock safety switch ensures machine shutdown when cover is open

- Emergency stop button

- Seal Bar Safety Sensors prevent damage to the product