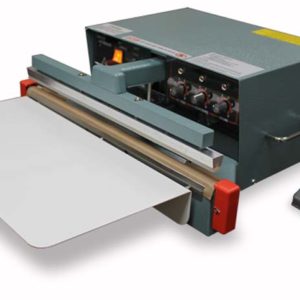

Features

Operating Features

- Adjustable seal head angle to accommodate product orientation

- Convenient footswitch cycle activation

- Rugged frame for stable, long-lasting performance

- Straightforward user controls help assure excellent results

- 3 year limited warranty

Sealing Features

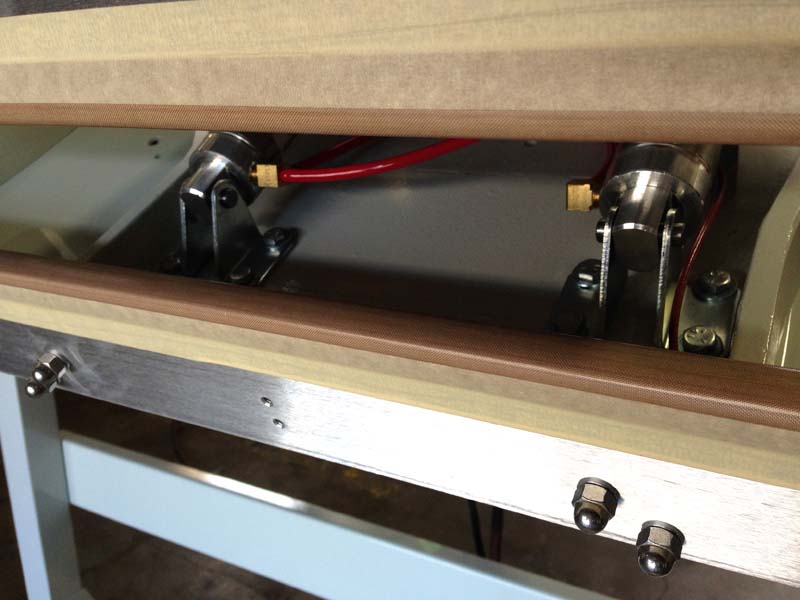

- Bi-active (top and bottom heat) pneumatically activated jaws for seal reliability

- Thermal impulse time control system does not require any warm-up time

- SureTemp temperature controller ensures seal quality by maintaining seal temperature to a precise setting (optional)

- Bag stretcher minimize wrinkles in the seal (optional)

Safety Features

- Spring closing safety system with release if obstruction is detected

- Jaw close timeout with release when delay is detected

- High heat only present when seal jaws are closed and under pressure

- Heavy duty seal transformer with thermal overload protection