Durable High-Performance Shrink Tunnels

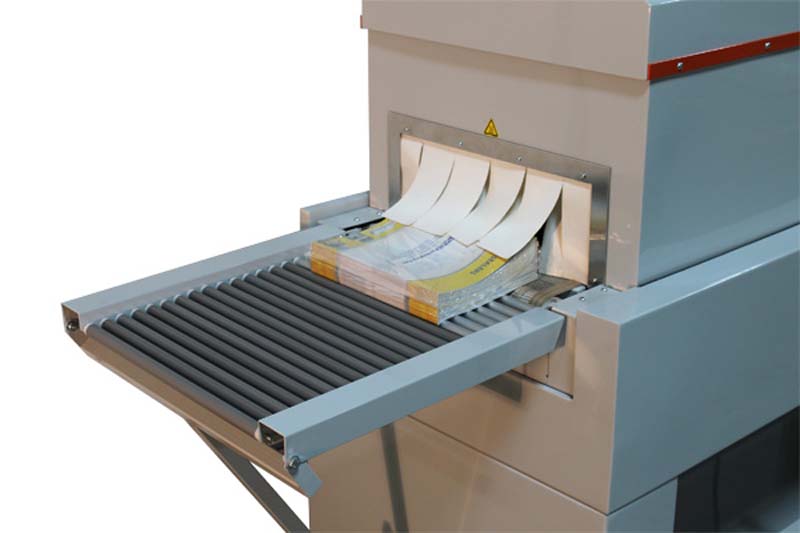

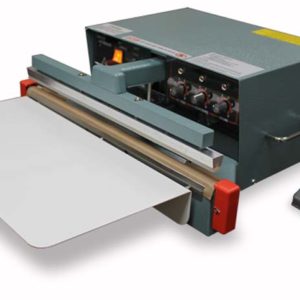

The Clamco Heavy Duty Extra Large Heat Shrink Tunnels feature extra length when compared to our standard heavy duty tunnels and are perfect for packing, sealing, and shrink wrapping larger size products. The extra length can also accommodate longer shrink time at a faster pace or film that requires a lower shrink temperature. Due to their precise temperature and speed controls, Clamco extra length tunnels are perfect for shrinking a wide range of films, from the lightest polyolefin to the toughest polyethylene films. Combine this durable shrink tunnel with the heavy duty Clamco L-Bar Sealer or our versatile 6800CS Side Sealer to create a complete shrink system.

These high-performance tunnels are engineered with 360° airflow and two blowers to further enhance control of film shrink. Optional dual zone controls can be used to set two different temperature zones in the tunnel chamber. Optional independent air velocity control allows the user to adjust the speed of each blower to optimize airflow in the tunnel, especially important at high speeds.

Clamco extra large tunnels are built with automatic cool down and shut off to extend the life of the tunnel. The tunnel curtain design and tunnel insulation minimize heat loss, maintain tunnel temperature consistency and keep outside tunnel panels cooler. Optional external fans help cool the product and complete the shrink cycle.

These Clamco tunnels are heavy-duty 24/7 machines with unique microprocessor controls for consistent shrink on a variety of applications. Count on Clamco extra large shrink tunnels for dependable performance.

Clamco 4Tx2, 6Tx2 and 8T Series Extra Large Heat Shrink Tunnels are made in the USA and include a 3-year limited warranty.

Leasing Options from $240/month